Sublime Results

With the advent of truly high-tech technology, the food industry has stepped up its game to keep up and a pastry chef has taken her desserts up to an uncommon level. This article was first published in the second issue of WIEF In Focus magazine.

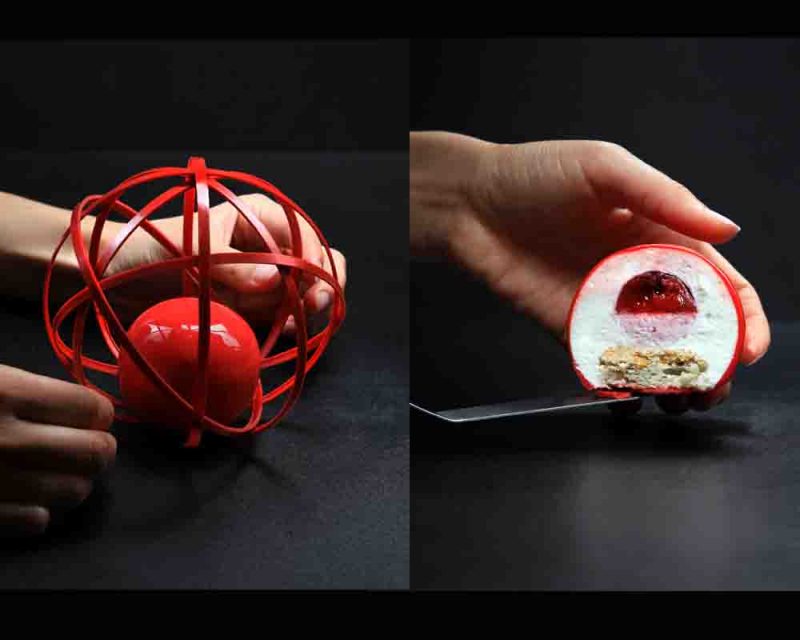

The best way to describe 29-year old Dinara Kasko’s desserts is that they are precisely sculpted, uncommon edible forms. The architectural student from Ukraine is a self-employed pastry chef in Kharkiv, Ukraine, who uses her design and technical background for sublime results.

‘At first, all I wanted was to create my own moulds and I didn’t know how to realise my idea. So, I used cardboard and metal shapes,’ Dinara recalls. ‘My ideas appeared to be too complicated and I decided to create models first out of some solid material and very accurate sizes.’ That was when the idea of 3D printing crossed her mind and the rest, as the sublime results prove, is history. Since then she had been creating moulds this way.

‘It might be a coincidence or it might not, but just then, a very famous Spanish magazine asked me to write an article about the connection between architecture and pastry art. And I did. Since then, I’ve kept working in this direction,’ explains Dinara, who’s also a mother of a 3-year old little girl.

While Dinara’s been baking for six years and teaching it for three, she’ll only admit to being a pastry chef for the last two years. It’s because, this is when she feels that she has gained enough experience. She created her first mould around two and a half years ago and have been teaching others make their own for about a year and a half.

Tools of Her Trade

Dinara’s architecturally-influence designed cakes are made possible due to the precision of 3D printing.

She admits to design and technology playing vital roles in her creations. 3D models for the mould are created on the computer using various software such as 3ds Max, Autocad and Grasshopper before anything else can happen.

Then, an Ultimaker 3D printer realises physically what has been on screen. ‘There are times when I do use a milling machine as well as a laser machine,’ she adds. ‘I read a lot of books to learn something new. Recently, I bought a compressor. And of course, I use a lot of different pastry tools.’

One of Dinara’s most impressive creation is an 81-piece algorithmically-modelled cake featuring Barry Callebaut’s ruby chocolate. For this creation, she used the software Grasshopper to create the mould for each piece which was inspired by the geometric paper sculptures of Matthew Shlian. Her structurally remarkable creation was part of the unveiling of the fourth type of chocolate in Shanghai in 2017.

Dinara’s one wish if she can better the technology she uses is, that modelling software to be more clear and simple to use. ‘Everything is in English and it can be an issue at times,’ she says and after some thought adds, ‘I’d like 3D printers to print much faster.

Actually, for my work I’ve all the necessary stuff. I just don’t have any assistants who can help me and I always lack time for my work.’

Uncommon Edible Forms

Despite the significant ease technology offers her, Dinara takes about a month to create a new mould and a new recipe. ‘Of course, the time varies,’ she says when asked about duration from inception to finished product. ‘It usually takes several tries to get the mould I want. It’s almost impossible to create something new in a week. If we are talking about moulds that have already been created and the recipes that have already been developed, then it’s possible to bake numerous cakes in a week.’

The challenges Dinara faces during the creative process include finding time to create a 3D mould and a recipe, to persevere when the first attempt doesn’t turn out well and, she adds, ‘It’s work that exhausts me at times, both mentally and physically.’ After saying that, Dinara admits to liking all the steps involved. ‘Every single step is interesting in its own way. It’s interesting to work on ideas. It’s interesting to take a look at what we get after printing and at the silicone mould we get. It’s interesting to make experiments with recipes, to taste cakes and so on. All the steps are interesting because these are steps to something new.’

Besides attending one of Dinara’s classes or an event which she happens to be a part of, there’s no other way to experience her cakes or their extraordinary forms. ‘I don’t create made to order cakes because I don’t have time for that. Since I don’t have any assistants, who’d help me? I only create moulds based on my ideas,’ she stresses.

Last Words

Citing that inspiration is everywhere and in everything, Dinara’s cake- making journey started with simple shapes and equally simple recipes. ‘At first, I used someone else’s recipes before I started bringing something of my own into it,’ Dinara recalls.

‘Then, I started creating my own moulds and my own recipes. As for the evolution of my creations, I try to create cakes of my own style, so people could recognise they’re mine from how they look. I work a lot on recipes, textures and flavours. I try to keep working in this direction and keep creating something new,’ she says with an easy smile.

‘I like all desserts. But good quality ones,’ Dinara confesses before concluding the interview. ‘I like cakes of different flavours and of different textures. I like ice-cream, eclairs, cookies and so on. I often cook traditional cheesecakes as they are low in sugar and are very healthy.’

The point to take home from that is, cheesecakes are considered healthy. Well said, Dinara. We wholeheartedly concur.

___________________

For more on the latest topics related to business, technology, finance and more, read our digital versions of In Focus magazine, issue 1,issue 2 and issue 3.