Lighting up green energy

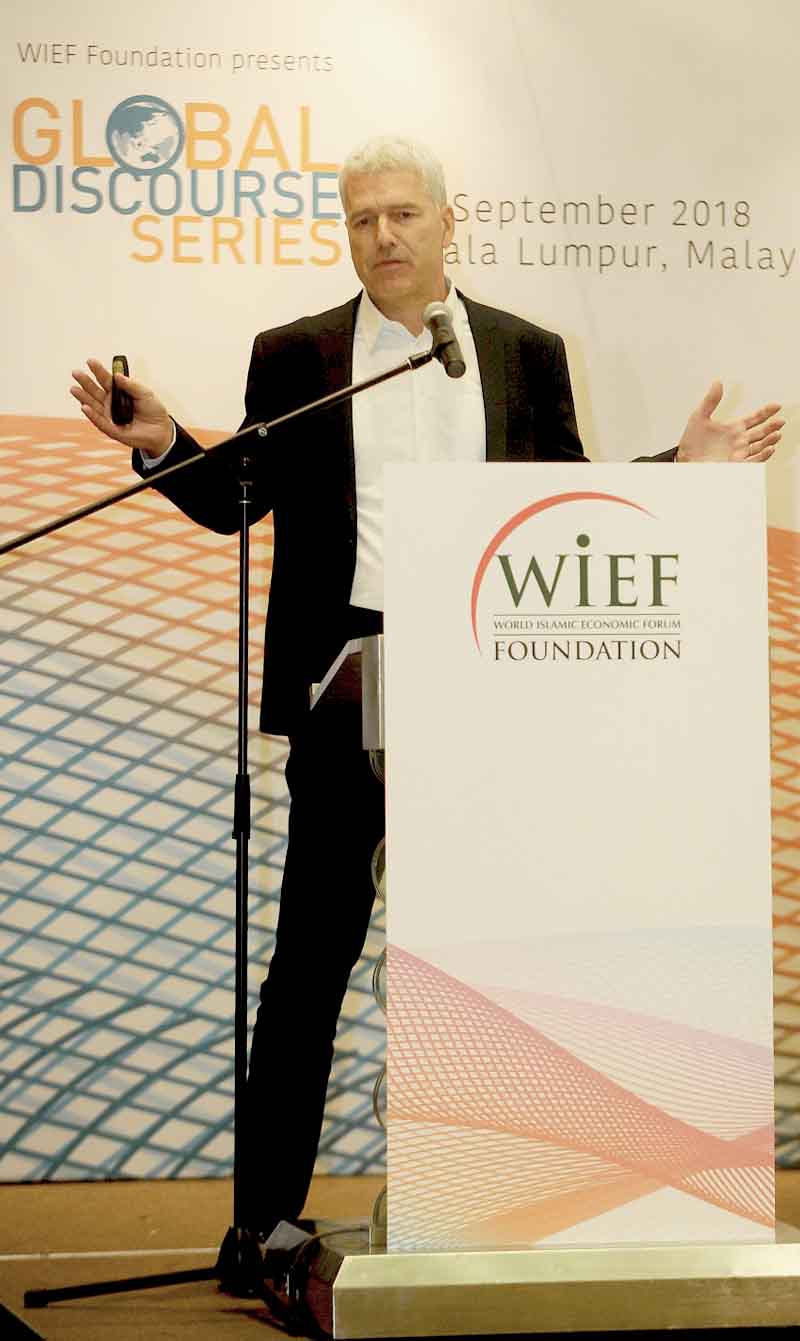

Combine efficient lighting technology with green technology and you get double the sustainability factor. Innovation Performance Versatility LED, (IPVled) does just that. It provides the latest light emitting diode (LED) solutions with thermal technology to provide sustainable and versatile lighting alternatives while reducing greenhouse gas emissions. Founder of IPVled and speaker at the upcoming WIEF Roundtable on green economy, Wilson Teng, explains more.

Here’s a fact: Innovation Performance Versatility LED (IPVled), a light-emitting diode (LED) lamp brand that combined German and Japanese technology lighting products, consumes 70 – 80 per cent less energy than any other light source. This fact alone changes the way energy is being consumed.

Right now, IPVled system is used for infrastructure and large building projects, which helps to reduce maintenance costs, provides better light performance over distance and optimises return on investment.

IPVled lights undergo rigorous internal testing to check the lifespan of the light. ‘The only way we can do it is to boil the whole light,’

Chairman and founder of IPVled, Wilson Teng impresses that IPVled uses little material in itself, making it much lighter than high-pressure sodium (HPS) lights and easier to install as well as transport.

IPVled lights undergo rigorous internal testing to check the lifespan of the light. ‘The only way we can do it is to boil the whole light,’ and that’s not all, they also ‘Light up the light and boil it in hot water, and then immediately quench it into a bucket of ice water,’ Teng says.

This is the thermal shock test, to see if there’s any water or moisture getting into the light and if the light can perform as it is in hot temperature, and how their heat exchanger disperses the heat.

Developing IPVled

IPVled research and development phase began in 2012 in Germany and Singapore. In 2015, IPVled Lichttechnik Pte Ltd was officially established in Singapore with the aim to become the leader in premium high-power LED products. Teng is also the inventor of IPVled. He created the entire luminaire design and put all the best technologies together from Germany, Japan and others.

It has high-performance bright lights that beat competitors. It’s a featherweight product, universal and is made up of interchangeable parts. It’s upgradable and has a modular technology, where a single body kit can be used for multiple applications. ‘Anyone can integrate our products with solar technology, like for example for solar street lights,’ Teng explains.

‘Industries here in Malaysia should be thinking forward and thinking long-term,’ says Mohd Hanafiah Abd Wahab, director of IPY Vision Sdn Bhd, a distributor and installation company of IPVled in Malaysia.

So far, they have installed IPVled lights in Samchem Sdn Bhd chemical warehouse in Shah Alam, which houses 10,000 over chemical drums and in a shipyard by the sea in Lumut, Perak. ‘Both are proof of the durability and standards of the lights. It’s safe in a chemical warehouse and doesn’t corrode,’ Wahab notes.

IPVleds’ recent installation was in Cahya Mata Sarawak (CMS) cement plant in Kuching. IPVled presented their technology as a better lighting alternative and saving energy solution to the group’s managing director Dato’ Richard Alexandar John Curtis and he liked it. Curtis, on behalf of Infra Trading Sdn Bhd, a CMS joint-venture company with the Sarawak Economic Development Corporation, signed a contract in 2016 with IPVled to become one of their channel distributors.

The IPVled high mast installation in the CMS plant reduced the colour temperature from 5000K to 2700K, giving 82 per cent enhanced luminance, reducing 78 per cent of energy and 65 per cent of maintenance costs.

Essential collaborations

IPVled has collaborated with many companies and government-linked companies (GLCs). State governments are either using them now or undergoing Proof of Concept (PoC) pilot projects in various countries such as Singapore, Malaysia, Indonesia, Thailand and Japan.

They have also been invited to countries such as Abu Dhabi, Dubai, Yemen, Egypt, Turkey and others. ‘Representatives from these countries have shown great interest to distribute our products. Some invited us to setup manufacturing plants in their country through Joint-Ventures (JV) or technology transfer business models,’ says Teng.

However, this innovative business idea doesn’t come without any challenges. According to Teng, their challenges appear especially at the management level because purchasers and even electrical technicians have a very minimal understanding of LED products.

He explains the resistance faced towards changing LED products is from employees on the ground level and sub-contractors from maintenance companies. Their fear of losing the golden rice-bowl and losing income by replacing conventional light bulbs is what causes the resistance. It is a known fact that LED is designed to have a much longer life span, thus reduces maintenance costs.

In order to overcome such resistance, IPVled needs to prove and convince company’s owners, top management, and high-ranking government officials at the ministry levels, to understand the pros and cons of implementing good LED products.

Most people only know LED products save energy, but very few people have actually gone further to understand how much they will save from the total cost of energy used. Teng lists other benefits that IPVled offers besides saving costs:

a) Better LED chips are brighter resulting in using less electrical power wattage.

b) Good designs of thermal solutions improve the life span of the products, thus last longer and reduce periodical maintenance drastically.

c) The impact of lightweight LED luminaires, especially in high power LED applications such as street lights, high mast and stadium lighting, will have great savings over structural costs using smaller poles or smaller structure due to its weight benefits.

Possibilities are endless

If you want to install this long lasting technology at home, the possibility is there but IPVled has no plans for it yet, mainly because there are already too many low-cost providers of the low power LED products and people do not care about quality. ‘People don’t usually look at the maintenance issues that will be faced until their LED luminaries fail,’ Teng says.

‘It is not how much you spend to reduce existing electrical bills, but rather what are your total savings over next five years or so,’ he clarifies. For example, if a company spends USD5 million over five years on their electricity bill with HPS lights, they can save 70 per cent or more of their total energy costs over the next five years or so. The USD5 million dollar electricity bill will instead be cut to USD2 million, saving the company over USD3 million.

As technologies evolve fast, competitors with similar technologies and other big and well known brands are available in the market but according to Teng, none of them that they know of so far feature exactly the same technology as IPVled.

Is it disruptive?

Though this may look like a disruptive technology, Teng believes IPVled is not disrupting traditional methods of energy supply companies. Rather the technology is inline with the current global focus to reduce emissions of carbon dioxide (CO2).

It is also going to solve one of the major problems today, which is that some countries do not have enough power to supply the entire nation. Many power-generating companies are facing coal and gas supply shortages and some claim they cannot purchase good quality supplies of coal.

‘LED products actually compliment the economy, by letting people spend less on electricity bills and gives them extra money to spend in other areas,’ Teng believes. ‘Any lighting company can have superb write-ups of technical specifications and other features, but one should let the users try it for themselves, see it themselves,’ he says. ‘Telling you I make the best cheesecake in the world will not make you believe it unless you taste it yourself.’ This is his common phrase to clarify this idea.

Elaborating on a similar point, Yahya Latiff, managing director of T21 Networks Sdn Bhd, a Southeast Asia solutions provider in the power and lighting industry, Malaysia, explains that every single brand out there will claim their product is the best in the market but the question is, in what way. ‘One could decide to spend less now but spend more in the long-run or be wise by investing now and enjoy longer term savings,’ he says.

‘That’s why we always emphasise on providing solutions and not just selling products, at the end of the day, it’s light we’re dealing with here and that’s why our stand on this is – seeing is believing,’ Latiff adds.

One of the recent cost savings examples this year (2017), of IPVled installations, is in Shah Alam. The company Samchem Sdn Bhd had previously spent USD100K on their lighting electrical bills and now they only pay 30 per cent of that amount. A whopping difference of USD70K. ‘Imagine what one can do with additional USD70K savings,’ Teng concludes, ending our interview on a positive note.